Asparagus Study

Full-Scale, Mixed Load Container Testing with Air Cleaned by Bluezone® Model 2400

Summary

After a 21 day test, Bluezone reduced red tip by 43%, tip rot by 47%, curved spear by 35%, and shrinkage by 76% in asparagus.

Objective

To determine the effectiveness of Bluezone Fresh Preservation Technology to reduce asparagus losses in a mixed FF&V container.

Methods and Materials

We conducted a side-by-side test of a mixed produce load over a 3-week storage period, to measure produce quality and the shelf life extension achieved with Bluezone Fresh Preservation Technology.

Configuration

- Two, 8’X8’X20’ Refrigerated Containers, each set to 34°F with ventilation sufficient to maintain CO2 below 1%.

- Mixed produce load of ethylene sensitive and ethylene producing FF&V.

- Temperature, humidity, carbon dioxide and ethylene measurements taken at regular intervals.

- One container with Bluezone, second container without Bluezone.

Duration

- 21 Days of Refrigerated Storage

- 5-10 Additional days of ambient temp storage for specified FF&V

Results

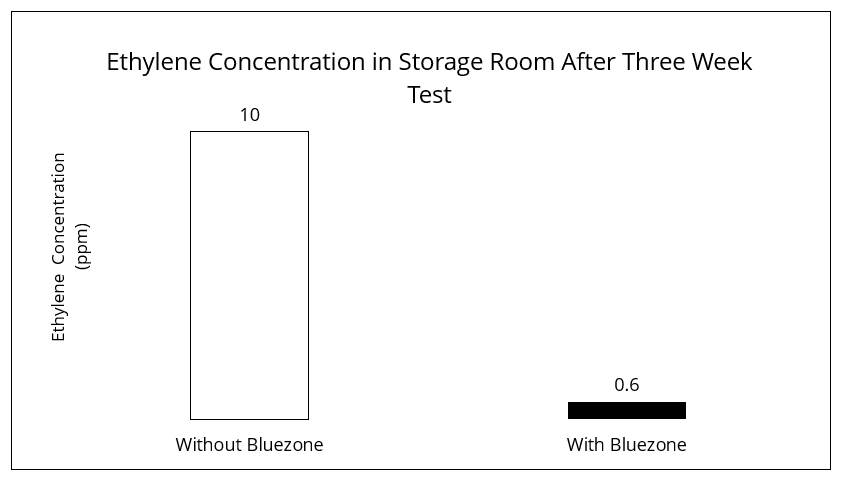

The Bluezone Model 2400 maintained ethylene concentration in the mixed load container at 0.6ppm throughout the 21-day test. Uncontrolled ethylene concentration was 10ppm.

This dramatic reduction in ethylene concentration had a significant impact on the quality of ethylene sensitive produce, such as asparagus.

Test Results for Asparagus

Storing asparagus in a mixed load environment with Bluezone operating to clean the air of ethylene significantly decreased asparagus damage. At the end of the 21 days of testing, the asparagus stored with Bluezone operating experienced significant reductions in loss including: red tip by 43%, tip rot by 47%, curved spear by 35% and shrinkage by 76%.

Conclusion

Use of Bluezone Fresh Preservation Technology in mixed produce storage significantly reduced the losses of asparagus generally caused by ethylene.