Garlic Study

Full-Scale, Mixed Load Container Testing with Air Cleaned by Bluezone® Model 2400

Summary

In a three week test, Bluezone reduced cracking in garlic by 39%.

Objective

To determine the effectiveness of Bluezone on garlic damage in a mixed FF&V container.

Methods and Materials

We conducted a side-by-side test of a mixed produce load over a 3-week storage period, to measure produce quality and the shelf life extension achieved with Bluezone Fresh Preservation Technology.

Configuration

- Two, 8’X8’X20’ Refrigerated Containers, each set to 34°F with ventilation sufficient to maintain CO2 below 1%.

- Mixed produce load of ethylene sensitive and ethylene producing FF&V.

- Temperature, humidity, carbon dioxide and ethylene measurements taken at regular intervals.

- One container with Bluezone, second container without Bluezone.

Duration

- 21 Days of Refrigerated Storage

- 5-10 Additional days of ambient temp storage for specified FF&V

Results:

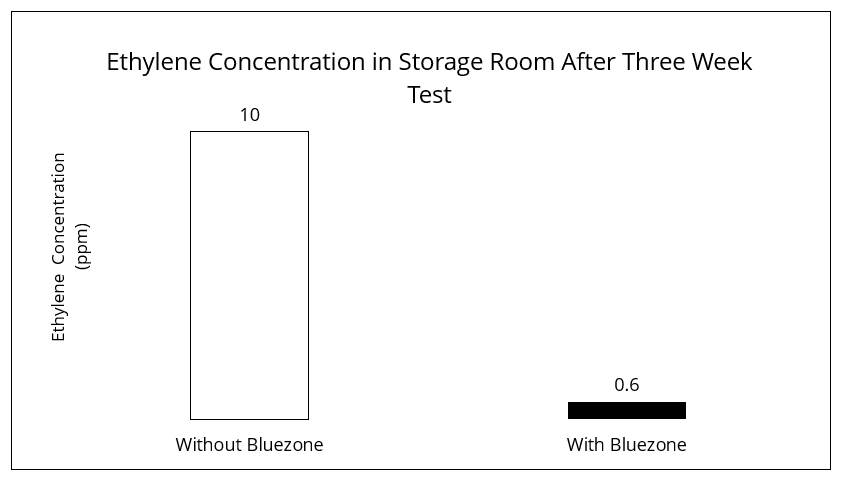

The Bluezone Model 2400 maintained ethylene concentration in the mixed load container at 0.6ppm throughout the 21-day test. Uncontrolled ethylene concentration was 10ppm.

This dramatic reduction in ethylene concentration had a significant impact on the quality of ethylene sensitive produce, such as garlic.

Test Results for Garlic:

Storing garlic in a mixed load environment with Bluezone operating to clean the air of ethylene reduced cracking by 39%, sprouting by 4% and surface mold by 2%.

Summary:

Use of the Bluezone Fresh Preservation Technology significantly reduced cracking in garlic over the 21-day storage period.