Kiwifruit Study

Field Test of Kiwi Storage with Bluezone® Fresh Preservation Technology

Summary

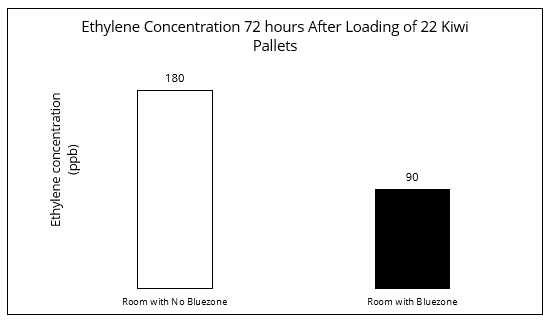

In a field test performed in a kiwi cool room, Bluezone decreased ethylene concentration by 50%, even at higher temperatures when ethylene production in kiwis increases.

Objective

This test was conducted to demonstrate the reduction of ethylene concentration achieved by Bluezone in a cool room filled with kiwis. A secondary objective was to determine if kiwis could be stored at a higher temperature with the use of Bluezone.

Methods and Materials

The test was conducted in two identical cool rooms, A and B, in a fresh produce warehouse. The rooms have the capability to store 80-100 pallets of produce. Both rooms were loaded with the same quantity of kiwi fruit sourced from the same shipment. Room A did not have a Bluezone. Room B had two Bluezone 2400 units installed at floor level. Both rooms were equipped with identical temperature controllers, refrigeration units and quick action doors to prevent entrance of VOCs and limit the loss of cool air. Room B was set at 1°C higher than Room A to determine if Bluezone could maintain ethylene levels low at a higher temperature.

Ethylene concentration was measured at the beginning of the trial using a ppm RAE. Both rooms were found to have near identical ethylene concentrations at the time of loading. Samples were taken from Room A, B and the main warehouse 72 hours after loading.

Results

Ethylene in Room A, no Bluezone, was 180 ppb after loading 22 pallets of kiwi into the room. Ethylene in Room B, with the Bluezone, was 90 ppb or 50% lower than Room A after loading 22 pallets of kiwi into the room. Despite Room B being 1°C higher (higher temperature enables kiwi fruits to release more ethylene) the ethylene concentration was still 50% lower.

Conclusion

Bluezone extends the shelf life of kiwis and allows kiwis to be stored at a higher storage temperature. A higher storage temperature of approximately 1°C might provide a significant saving in energy costs.