Tomato Study

Field Test of Tomato Pack House with Bluezone® Fresh Preservation Technology

Summary

In a five week test, Bluezone reduced mold by 30% in a tomato packing shed.

Objective

Test the anti-microbial performance of the Bluezone® Fresh Preservation Technology Model 2400 in a packing shed where hydroponically grown tomatoes are packed and outbreaks of mold have led to losses of product.

Methods and Materials

The anti-microbial performance of Bluezone was evaluated by conducting before and after air sampling at several locations within the pack shed using standard bio-aerosol sampling procedures. Sample plates were then incubated and counts made of the resulting colony forming units (CFUs).

The pack shed has dimensions of 45m x 35m and a ceiling height of 5.2m giving an air capacity of 8,190 cubic meters. Three Bluezone Fresh Preservation Technology units were installed by placing these under conveyors and packing equipment. This was recognized as being fewer units than that recommended from earlier research by the manufacturer, however, there were only three units available at the time the trial was to commence.

Figure 1: Location of Bluezone Model 2400 under conveyor in tomato pack house

A MicroBio MB1 Bioaerosol Sampler (http://www.cantiumscientific.com/MB1.html) was positioned inside the pack shed and connected to a vacuum pump. The sampling procedure was as follows:

- Install a Potato Dextrose Agar (PDA) Petrie dish in the sampler and start the vacuum pump drawing 50 liters of air on to each dish

- Remove PSA dish from the sampler

- Cover dish with lid, tape the cover to the dish, and place in an incubator at 20°C for 72 hours

- After 72 hours, remove PSA dish and count the colony forming units (CFUs)

It was important to establish a sampling protocol which would produce a high enough number of CFUs under the baseline (no Bluezone) conditions so that any anti-microbial effect of the Bluezone could be discerned. Multiple samples were taken at the start and finish of the trial period as by its very nature, microbial testing leads to large variability in data. The air sampling exposure time for all agar dishes was the same as the incubation time.

Results

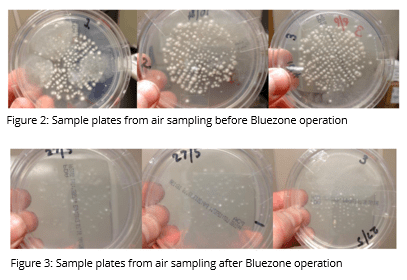

The dishes in Figure 2 are from three locations in the pack shed before Bluezone installation; those in Figure 3 are from the same three locations in the same pack shed five weeks after Bluezone installation. The mold in Figure 2 was later grown out by extending the incubation time a further three days and the molds were identified as a mixture of Penicillium and Rhizopus stolonifer.

Examining these photos shows a clear reduction in number of CFUs with the Bluezone in operation.

Conclusion

Installation of the Bluezone units in this environment resulted in significant reduction of mold CFUs and retardation of their growth time, with quantitative reduction of at least 30% over the duration of the test.